We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

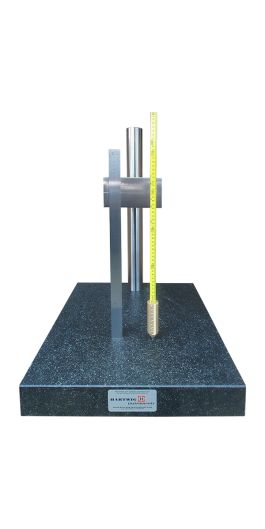

Linear working tape verification setup

ISO 17025 RvA accredited Linear working tape verification setup.

This linear verification setup for working tapes is intended to use with Hartwig Class 1 measuring tapes.

To meet your scope or simply just to check if your measuring tapes that are used in the field are within specs.

This setup uses a ISO 17025 calibrated measuring rod, 500mm long, and can be dismounted for annual recalibration.

ISO 17025 RvA accredited Linear working tape verification setup.

This linear verification setup for working tapes is intended to use with Hartwig Class 1 measuring tapes.

To meet your scope or simply just to check if your measuring tapes that are used in the field are within specs.

This setup uses a ISO 17025 calibrated measuring rod, 500mm long, and can be dismounted for annual recalibration.

All is mounted on a big marmer block for stability and accurate - level mounting.

Operation:

The Linear verification setp is used to check the first 0 - 450mm of your measuring / oil gauging tapes.

On the left of the holder is a SIO 17025 calibrated measuring rod of 500mm long with mm scale. this rod has a thickness of 6mm and is 30mm wide that provides a static rod.

The measuring rod is mounted on a plate with an engraved base line, this line will match a pre fixed height such as 400mm.

on the other side of the rod you can hang your measuring or oil gauging tape for verification, lower it down with great care just to tip the marmer block with your dipweight. when the dipweight ticks the marmer, follow the engraved base line and read your gauging tape. when your gauging tape is still accurate you should see that the base line is lined out with the 400mm of rod and measuring tape.

- easy to work with

- ISO 17025 calibrated rod

- static marmer block

- linear setup uses the tension strength of the tape itselves

- most failures in gauging tapes are within the first 50cm of the tape or tape to dipweight connection

- durable solution

- easy to log and register for operators